TRENNSO-TECHNIK® develops, plans and builds customised systems and modules. These are used in the dry separation process for separating and sorting in recycling, the processing of bulk materials and in the food industry. The family of our screening machines has recently received a highly potent addition: The SIS screening machine. This screening machine also maximises user-friendliness, efficiency and time savings when changing screens and cleaning.

SIS SCREENING MACHINE: TIME-SAVING, EFFICIENT

Screening machines for classifying granular products

In the field of screening technology, TRENNSO-TECHNIK® manufactures various series of screening machines. These are efficient in screening bulk materials of different grain sizes. The material should not exceed a certain moisture content and should be free-flowing. All machines from TRENNSO-TECHNIK® meet the increasing quality requirements of industrial recycling. However, the customised screening machines from Weissenhorn are not only used in the recycling sector, but also in the food industry and in the processing of bulk materials.

Experience: Offering new solutions

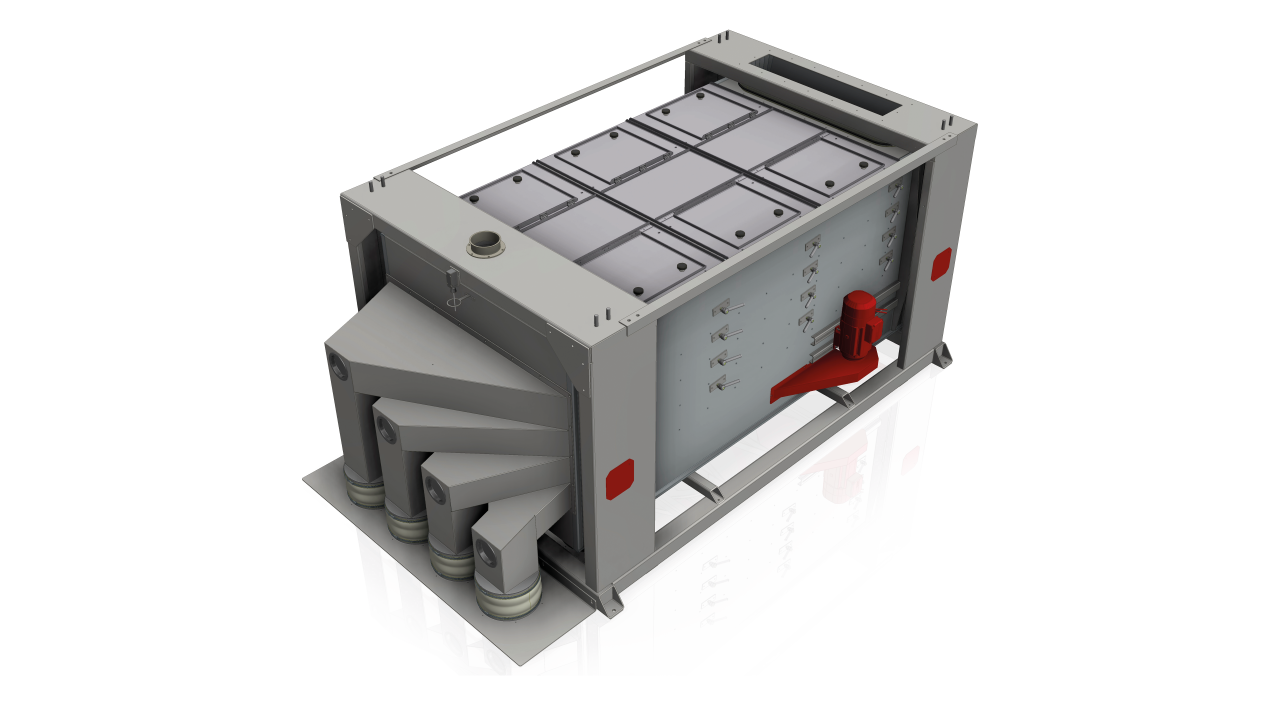

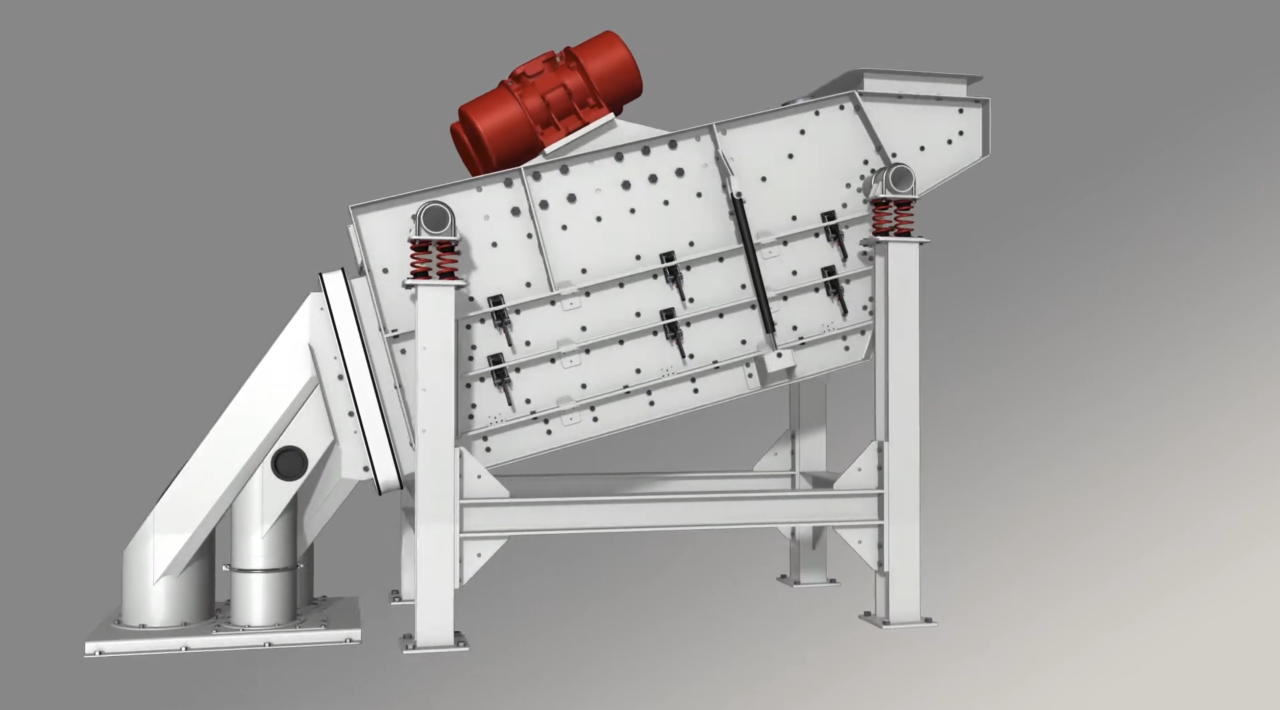

The team at TRENNSO-TECHNIK® is always endeavouring to offer our customers new, more efficient solutions for separating and sorting. This is how the new SIS screening machine came about. It is a further step towards the highly productive screening of even coarse-grained and moist products. This process efficiency is combined with user-friendly maintenance, simple screen changes and uncomplicated cleaning. The new machine design and the components used support maximum user-friendliness / usability.

How it works: How to sieve efficiently

The screenings are fed into the screen box via a distribution device. The screen box is mounted on steel springs on a solid steel frame and is dust-tight. Two overhead unbalance motors cause the screen box to vibrate. The screens are inserted into the screen box and can be easily changed thanks to the unique swivelling mechanism. The video shows a clear animation of the machine:

By playing the video, you consent to the Google Privacy Policy Show more

We would like to point out that after being activated (consent according to Art. 49 Para. 1 P. 1 lit. a GDPR), data will be transferred to YouTube/Google ( Google Privacy Policy ) in the USA. The USA is considered by the European Court of Justice to be a country with a level of data protection that is inadequate by EU standards. If you do not use YouTube, the transfer described above will not take place.

Close overlayFeatures: Two sieve layers for optimum results

The SIS screening machine consists of two screening layers as standard. The upper sieve layer is a solid 3D honeycomb sieve for coarse sieving. The lower sieve layer is a PU expansion shaft. Of course, it is also possible to equip the machine with round hole and square mesh screens in mild steel and stainless steel.

The screen sizes and hole sizes can be freely selected according to customer specifications. The stroke and speed can be variably adapted to the product in order to achieve optimum throughput and precise classification of the material to be screened. The sieve can also be connected to an aspiration system.

Options: TRENNSO-TECHNIK® delivers made to measure

The SIS screening machine is available in various widths and lengths. Current machine sizes are 500 mm screen width, 1800 mm screen length and 1000 mm screen width, 3000 mm screen length. For individual machine dimensions, please contact us, as every machine at TRENNSO-TECHNIK® is a customised solution according to customer specifications. Depending on the application or abrasiveness of the material to be separated, different wear lining variants are available, e.g. HARDOX, PU, stainless steel. A complete design in stainless steel and surface finishes to meet requirements are also available.

Unbeatable: Advantages of the SIS screening machine

The SIS screening machine is the next generation of screening machines from the separation and sorting technology specialist from Weissenhorn, TRENNSO-TECHNIK®. In addition to the well-known high product quality and compatibility with other modules from TRENNSO-TECHNIK® in the field of processing plants and dry separation processes, the SIS screening machine offers further advantages. The simple screen change reduces downtimes and increases your plant availability. The screen levels can be released individually and brought into the horizontal position. The individual levels are not additionally bolted but are held in position by the locking force used. Another advantage is the suitability of the SIS for damp, coarse and angled material. From 0 to, for example, 300 mm, whatever comes onto the screens is separated!

Technical centre: It's all about the experiment!

As a valuable process component between planning and production, our customers can rely on the technical centre at TRENNSO-TECHNIK®. We can carry out tests with customer material in this state-of-the-art, fully equipped test facility. The new SIS screening machine is also already available here for testing purposes. We would be happy to carry out trials with your product. Simply make an appointment request by telephone or use our utilisation request form on our company page. What can our systems screen for you? We look forward to your task!

Questions about sorting technology? Call TRENNSO-TECHNIK®!

If you have any questions about sorting technology such as our screening technology or density sorting technology, we will be happy to inform you about our machine portfolio. Special feasibility enquiries can be carried out in real life through tests in the technical centre of TRENNSO-TECHNIK® in Weißenhorn. Our trained team in the technical centre will be happy to assist you by prior appointment.

We look forward to receiving your enquiry: Tel. +49 730996200 or an email info@tst.de