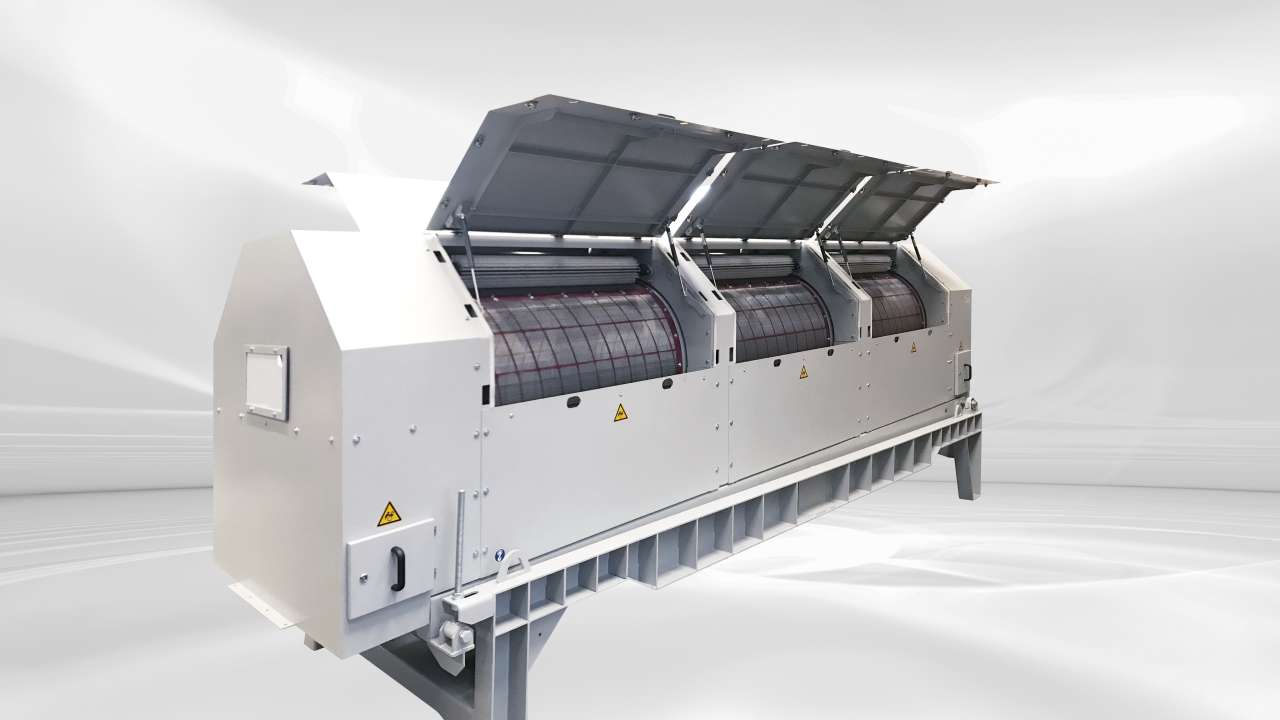

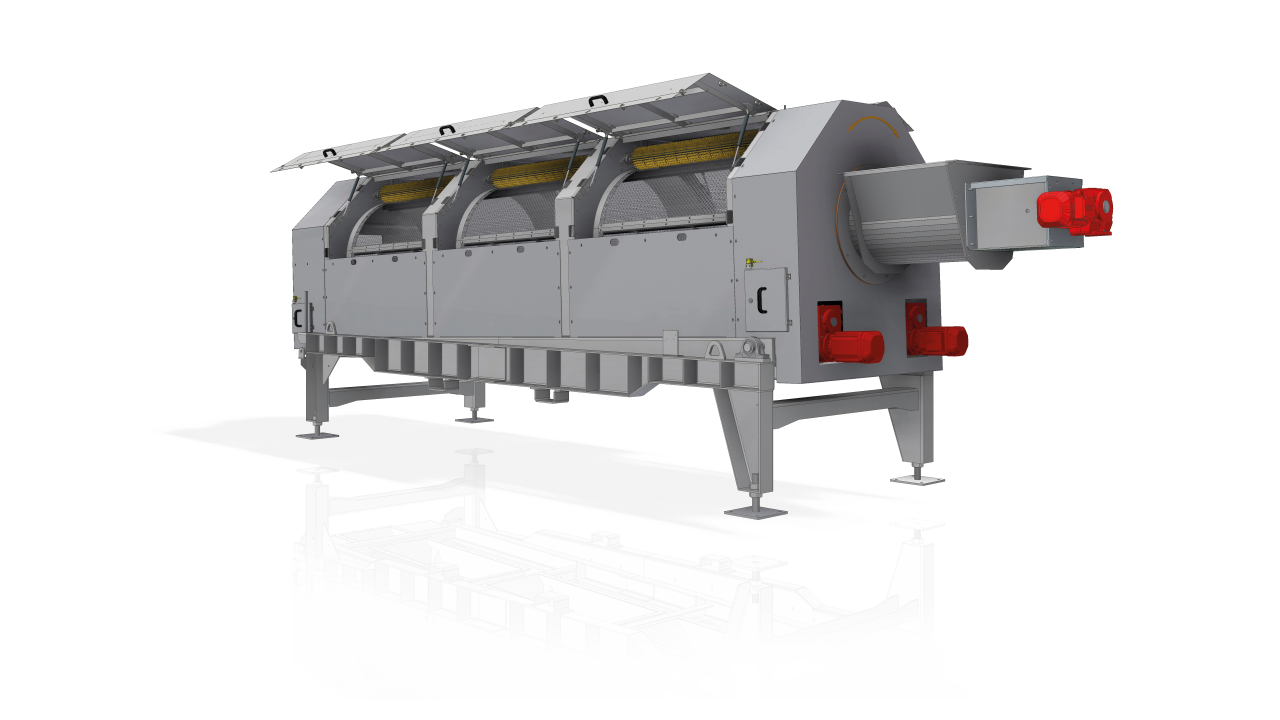

Drum screening machines filter, separate and screen various materials in different sizes via a perforation in the so-called drum screen and are used in many areas of the processing industry. The screened material is fed into the trommel screening machine or directly into the rotating screening drum by means of a feed screw, conveyor belt, elevator or vibrating chute. The screen drum can be covered with anything from coarse perforated plates with stainless steel mesh to mesh with fine perforations. A built-in spindle then feeds the material over the different screening drums. The speed or capacity of the drum can be variably adjusted using an on-site frequency converter. The inclination of the drum screen can be variably adjusted from high to low, depending on the version.

Depending on the design of the drum and drum screen, screening is possible in up to four output sizes. Large maintenance covers on the drum screening machine make it easy to clean the individual screen coverings and change them if necessary. Cleaning options using cleaning rollers and permanent compressed air cleaning are also available as an option.

DRUM SCREENING MACHINE BY TRENNSO-TECHNIK®

OPERATING PRINCIPLE

Functionality of the drum screen

The trommel screening machine sorts the bulk materials into different grain sizes thanks to the variable design of the screening drum. In order to achieve a suitable result, the products must be free-flowing and should not exceed a certain moisture limit with regard to the trommel screen. These requirements also ensure the high quality processing of the material with our machines.

Options when purchasing a screening drum from TRENNSO-TECHNIK®

Continuous cleaning via cleaning rollers and permanent compressed air cleaning of the screen drum and drum filter are also available on request.

Complete versions of the entire machine as well as the drum and drum screen in stainless steel and customised surface finishes are also available. Please feel free to contact us by e-mail, telephone or fax.

Are you interested in one of our trommel screens or do you have questions about the machine's technical data?

Contact us by email or give us a call for non-binding advice on our trommel screening machines. In addition, we offer our customers the opportunity to view and test our machines, such as screening plants, in the in-house technical centre of TRENNSO-TECHNIK® so that you can see for yourself. So you can see the plants for yourself.

We look forward to receiving your enquiry!

Your TRENNSO-TECHNIK® Team.