The separation of herbs and impurities requires a high level of experience, expertise and technology on the way to an aromatically pure raw material, all of which can be found in each of our solutions for impurity management in herb processing. For gentle treatment of your raw materials, our values go hand in hand with the customised production and commissioning of your system, which we design and implement to suit your specific production volume and requirements.

TRENNSO-TECHNIK® has extensive experience in the separation and sorting of foodstuffs with a purity result of 100%. With air classifier modules from TRENNSO-TECHNIK® the light materials are separated and the heavy materials are separated using downstream separating tables. Different types of screening machines are also available for any necessary or desired particle size fractionation. Of course, all machines can be realised with a surface finish that meets food hygiene requirements, e.g. manufactured in stainless steel, pickled, surface blasted or electropolished.

PLANT AND MACHINERY: HERB PROCESSING

Contact our experts for herb processing systems and machines

Do you have any questions or need personalised advice on processing herbs?

Contact our specialist directly and receive customised process engineering for your company. CONTACT

Our machines for efficient herb processing

Discover our comprehensive range of machines for herb processing:

From air separators and screening machines to destoners (separating tables or table separators) as well as the appropriate conveying and dosing technology. Our process technology is designed to ensure maximum efficiency and quality in your production process.

Air classifier - Effective pre-cleaning in herb processing

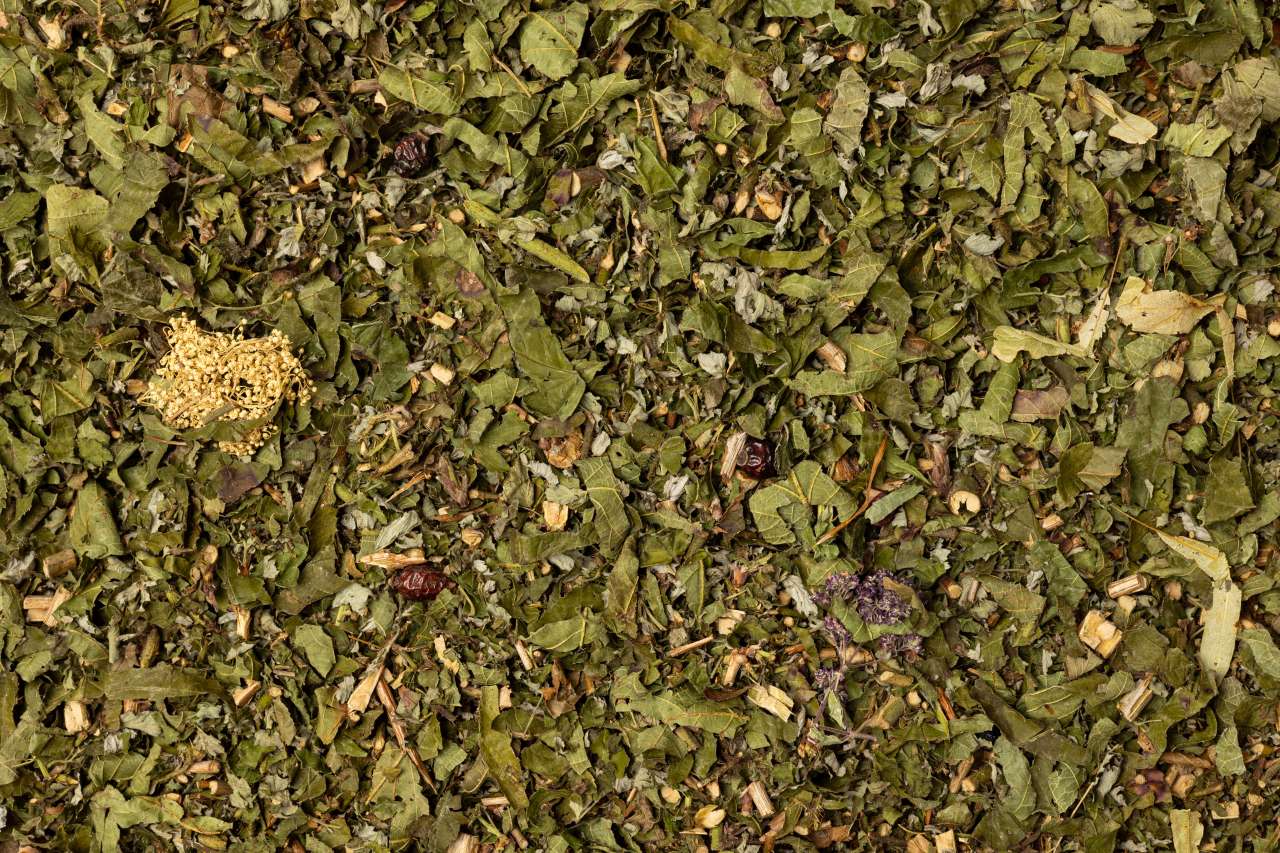

The first challenge in herb processing is to separate light impurities and contaminants such as dust, small leaves, packaging material and light metals from the herbs.

Our air separators use targeted air currents to efficiently remove these unwanted particles. This step is crucial to ensure the purity of the herbs right from the start.

Sieving machines - Precise sieving in herb processing

After pre-cleaning, our sieving machines precisely sieve the herbs according to size.

Smaller, heavier particles and impurities that affect the quality of the end product are reliably sieved out and larger particles can be returned for reworking in a granulator. Only the best and most uniform raw materials reach the next processing stage.

Destoner - final cleaning for pure herbal enjoyment

We use our separation tables (de-stoners or table separators) to remove the last remaining impurities and contaminants.

Through precise vibrations and a special surface these separate the herbs from heavy particles such as stones, glass, metals, etc.. This step perfects the purity of the herbs and ensures that only the highest quality raw materials are processed.

Mills

Feed-in

The bulk material is fed to the mills via conveyor and/or dosing technology.

Separation

Depending on the grinder, the bulk material is crushed, cut, ground, sphericalised, etc.

Output

Finer components of the bulk material are extracted.

Conveying and dosing technology - Efficient material flow in herb processing

With thorough cleaning, our conveying and dosing technology plays a central role in herb processing.

These transport the herbs gently from one machine to the next, without damaging the delicate product. The precise dosing ensures that exactly the right amount of herbs reaches the subsequent processing stages, which guarantees the quality and homogeneity of the herbs.

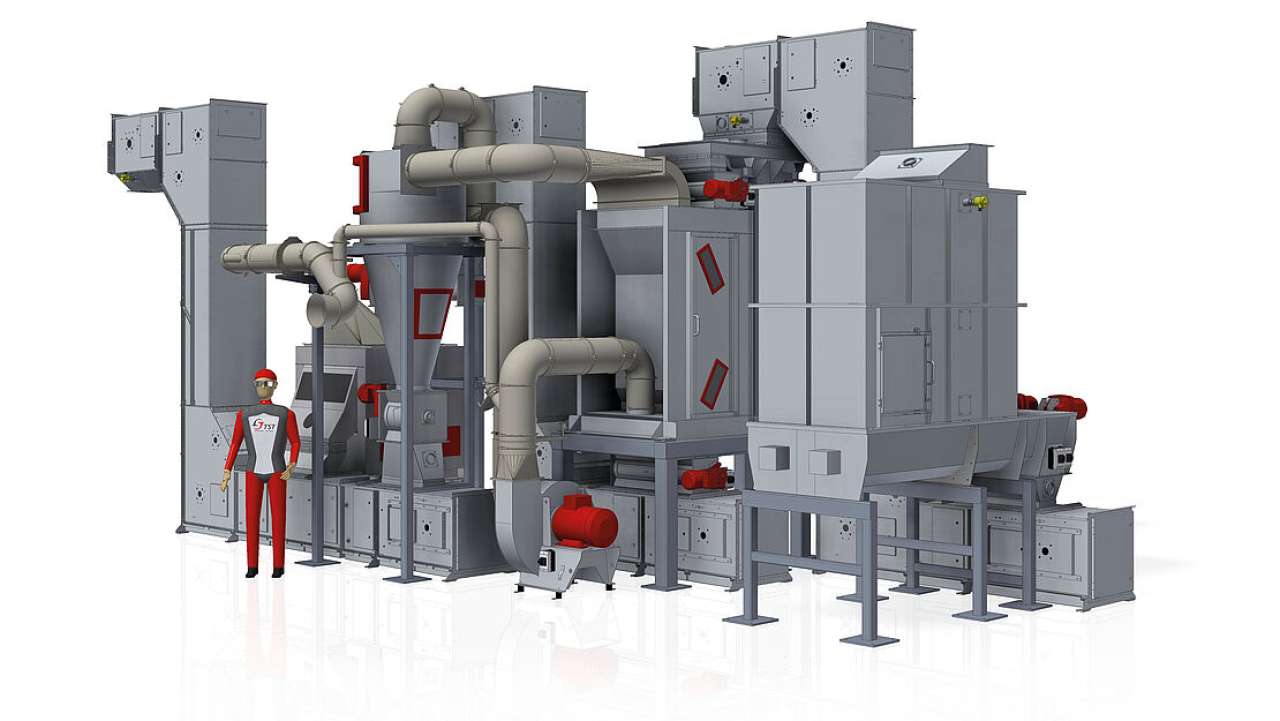

Complete herb processing plants - your turnkey process technology

Our systems and machines can be configured into a fully integrated cleaning system for herb processing.

The air classifier, screening machine, separating tables, conveyors and dosing systems work together seamlessly to form an efficient and precise cleaning system. Our process technology provides you with a turnkey solution that removes impurities and contaminants of all kinds and guarantees consistently high quality.

Herbs dried and separated from foreign bodies

Foreign bodies in herbs not only oversalt any soup, they can also lead to large-scale recalls with associated costs and health risks for customers. It is better to prevent this from happening in the first place and to remove foreign bodies from herbs reliably and effectively before they are sent for further processing. The dry separation technology from TRENNSO-TECHNIK® does exactly that: perfect separation of the raw material from foreign bodies and pure purity of herbs of all kinds.

Hygienic design for herb processing - EHEDG member

Our systems and machines comply with the guidelines of the EHEDG (European Hygienic Engineering & Design Group). The hygienic design of systems and machines ensures easy cleaning and prevents contamination. In this way, we fulfil the highest hygiene standards and ensure safe and clean production processes in herb processing.

Your path to project success - Plant and machinery for cheese processing

Our tried-and-tested processes ensure project success in herb processing.

Our structured processes guide you safely from the initial consultation to the commissioning of your customised and tailored process technology.

Advice - your first step towards optimised herb processing

Every project starts with a qualified consultation. We clarify your specific requirements at an early stage and can develop a customised concept for herb processing using a 3D scan of your production facility.

Test - Validation of your herb processing processes

In our in-house technical centre, we test various process technologies for your herb processing requirements under practical conditions. This enables us to find the optimum configuration for your herb processing process, whether it is a single machine or a complete system.

Concept - Customised solutions for your herb processing

Tailored to your requirements and based on the results of the pilot plant, we develop a customised process concept for processing herbs. In doing so, we take all relevant factors into account in order to achieve maximum efficiency and quality.

Finalisation - Working together to find the optimum solution in herb processing

After the intensive phase of consulting, testing and design, we work with you to finalise your customised process technology. The final plans for the engineering of your herb processing plant are drawn up in close consultation.

Design and engineering - from the plan to the finished herb processing process

Our engineers translate the jointly developed plans into precise technical process engineering. Every machine and every module is designed to be perfectly integrated into your herb processing process. By utilising the latest software and technologies, we guarantee that your herb processing system meets the highest requirements and functions smoothly.

Production - Made in Germany quality for maximum cheese purity

We manufacture your herb processing systems and machines with the highest precision in our own production facilities. A high level of vertical integration enables us to realise the highest demands in terms of quality, functional reliability and punctuality, so that you can guarantee your customers the best cheese purity.

Assembly of your herb processing plant or machine - precision on site

Our experienced professionals will install your machine or system directly on your premises. In this way, we ensure the high quality and functionality of your process technology for cheese processing.

Commissioning - starting signal for your production in cheese processing

We commission your plant or machine together with you and provide you with first-class process technology. At the same time, we train your employees for optimum operation in cheese processing with our machines and systems.

Service - support in herb processing whenever you need it

Our process technology is designed for continuous operation, is easy to operate and simple to maintain. Our service team will be happy to assist you at any time to ensure the smooth operation of your herb processing machine or system.

Long-term partnership - successful together in herb processing

Our co-operation does not end with commissioning. We attach great importance to a long-term partnership. As your reliable partner, we continuously support you in the optimisation and expansion of your cheese processing systems and machines to ensure that your production processes are always up to date. Our goal is to ensure your long-term success.

Efficient processing for the highest quality

“Whether coffee, tea, cocoa, nuts, spices, pulses, eggshells or herbs - the requirements for quality, purity and efficiency in processing are diverse. Our technologies help companies around the world to precisely separate, clean and optimise their raw materials. This results in high-quality end products that meet the highest standards.“

Contact form - Your direct route to optimised cheese processing technology

Fill out the form to receive more information about our herb processing technology. Our team will get back to you as soon as possible.

Telefon

+49 7309 96 20 0