The rotary valves from TRENNSO-TECHNIK® are used wherever bulk materials need to be discharged at a constant throughput rate. The pneumatic conveying units are also suitable for reliably dosed discharge and feeding of a certain number of products or for shutting off containers and cyclones. The material to be conveyed should have the optimum consistency for the cellular wheel, i.e. dust, powder or granular.

ROTARY VALVE FROM TRENNSO-TECHNIK®

PNEUMATIC CONVEYING FOR PRESSURELESS DISCHARGE AND DOSING RECYCLING OF IMPORTANT RAW MATERIALS

Pneumatic conveying and dosing of various materials with the properties of

Dusty products

Powdery or granular products

Rotary valves for all applications

Our rotary valves are typically used in zig-zag separators, cyclones, silos and bunkers for processing in the recycling, bulk goods and food industries. The rotary valves are installed upstream and downstream of zig-zag separators, trough screw conveyors, trough chain conveyors or screw conveyors in general, for example, in order to dampen the pressure of the silo material and ensure air exclusion. The rotary valve is also used under filters or cyclones. In this way, bulk materials can be removed from pneumatic systems with the lowest possible pressure loss.

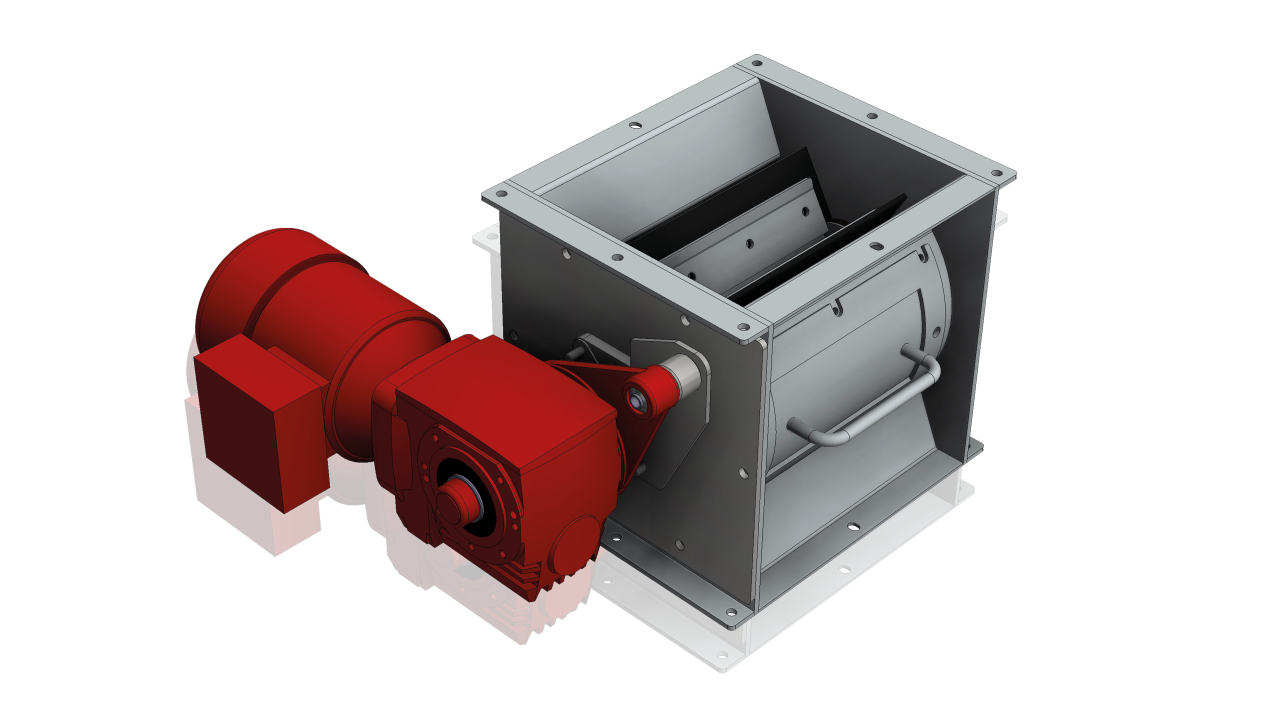

Function and structure of our rotary valves

The functionality of the pneumatic conveyor system is based on a rotor, the so-called rotary valve. This special component of the rotary valve rotates in a precisely fitting housing. When the system is used, each rotor cell takes in bulk material through the rotary valve, which falls out again via the outlet. This results in a volumetric continuous conveying of the components.

Special versions of our rotary valves

Housing, rotor and rotary valve made of stainless steel

Replaceable rotary valve buckets made of stainless steel

Different material designs for the rubber lips

Various wear protection solutions as required, including particularly hard and tough HARDOX steel

Openings in the rotary valve for professional maintenance

Including with particularly hard and tough HARDOX steel

Openings in the rotary valve for professional maintenance and installation of any spare parts

Designs in accordance with ATEX directives

Do you have questions about our rotary valves and their technical data or are you looking for the right pneumatic conveying system for you?

We are happy to support and advise you in the selection of your suitable filter system. Contact us by email or give us a call.

We look forward to your enquiry!

Your TRENNSO-TECHNIK® team.