Elevators (often also called bucket elevators) are mechanical continuous conveyors for the vertical transport of bulk materials such as grain and other powdery or granular bulk materials. Elevators (bucket elevators) are suitable for the continuous transport of various material quantities and conveying capacities.

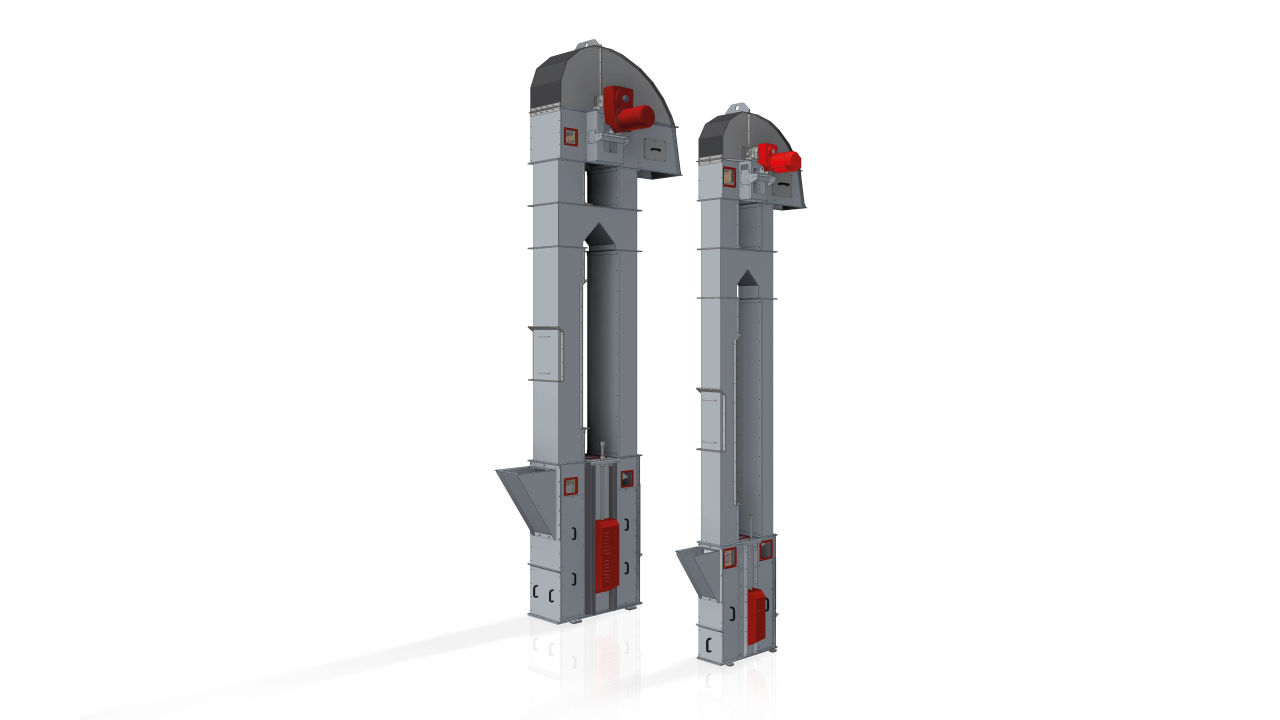

Elevators consist of an elevator foot, elevator bowl and the elevator shafts in which the belt or chain runs. On these belts and chains are containers in the form of buckets (belt bucket elevators, chain bucket elevators) or so-called carriers (chain elevators), which convey the bulk material with the help of a geared motor. Bucket elevators (belt bucket elevators) and chain elevators differ not only in the belts and chains used, but also in their conveying capacities. For example, bucket elevators can convey 60-150 tonnes per hour and chain elevators 40 tonnes per hour.

The buckets of the elevators can be loaded and unloaded at different points. The major advantages of belt bucket elevators or chain bucket elevators in modern conveyor technology are their long service life and energy-saving operation.

BUCKET ELEVATORS AND CONVEYORS

For economical vertical conveying - our belt bucket elevators / bucket elevators

For the vertical transport of powdery and granular bulk materials, we supply our elevators (bucket elevators) in standard or stainless steel design with high drive power as standard. If required, with replaceable wear protection such as against weathering in various qualities such as HARDOX. All elevators (bucket elevators) are supplied with large maintenance openings.

Vertical transport - bulk goods Properties

Powdery bulk solids

Granular bulk solids

Elevators & bucket elevators from TRENNSO-TECHNIK®

We also offer cost-effective complete solutions for high conveying capacities.

Our special designs

Bucket designs in stainless steel and plastic

Different belt designs

Various wear protection solutions as required, including with particularly hard and tough HARDOX steel

Electronic monitoring - misalignment monitoring and speed

Designs in accordance with ATEX directives

Do you have a question about our elevators & bucket elevators?

Contact us by email or give us a call.

We look forward to your enquiry!

Your TRENNSO-TECHNIK® team.