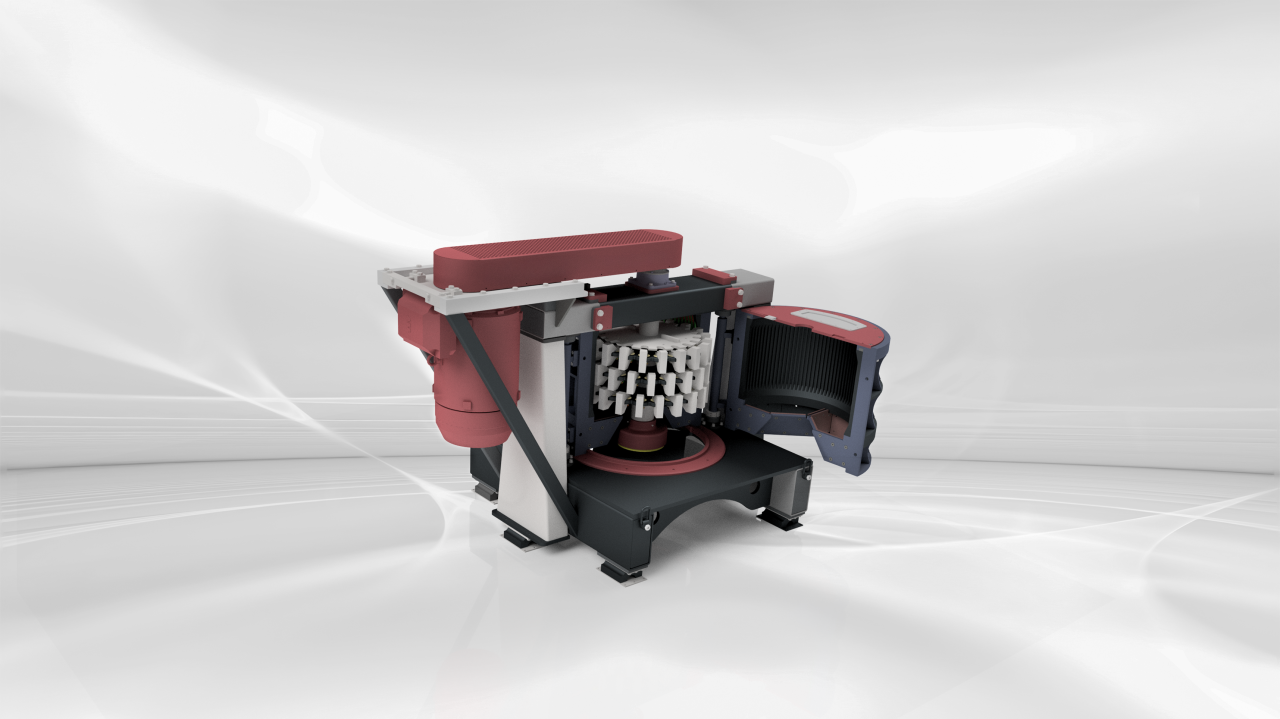

Our shredding units are designed for continuous operation under high loads - even with complex material composites. The wedge-shaped rotor ensures an optimised impact effect, while the speed and hammer spacing can be precisely adjusted.

The shredding is carried out by rotating hammers and fixed wear strips in the grinding chamber. An air flow effectively cools the mill and ground material, while the material is fed mechanically or pneumatically - via a screw, belt, vibrating chute or cyclone separator. The material can be discharged by suction or trough chain conveyor.

An electromechanical housing lock and integrated vibration monitoring ensure safety. Wear parts are easily accessible and can be replaced quickly - minimising downtimes during operation.

VERTICAL HAMMER MILL VEHA

FUNCTIONAL MODE

Area of application:

The VEHA vertical hammer mill is used for grinding pre-treated material < 50mm.

By playing the video, you consent to the Google Privacy Policy Show more

We would like to point out that after being activated (consent according to Art. 49 Para. 1 P. 1 lit. a GDPR), data will be transferred to YouTube/Google ( Google Privacy Policy ) in the USA. The USA is considered by the European Court of Justice to be a country with a level of data protection that is inadequate by EU standards. If you do not use YouTube, the transfer described above will not take place.

Close overlayDownload Factsheet

| Name | Type | Größe | Download | View |

|---|---|---|---|---|

| tst-factsheet_veha-en_06-2025 | 584.37 KB |

Are you interested in our mills or do you require further information?

Contact us by e-mail or give us a call and let us advise you professionally.

We look forward to your enquiry!

Your TRENNSO-TECHNIK® Team.