A pile of broken glass also has its good side! When it comes to recycling, glass is a grateful raw material. Not only is glass one of the longest recycled materials in the circular economy, but the efficiency of glass recycling also makes other industries look on with envy. Glass can be 100% recycled, can be melted down as often as required and saves a lot of energy compared to initial production. According to DUH, energy consumption in glass production has fallen by around 77% over the past 50 years. This is thanks to modern technologies and successful glass recycling. The focus here is on its use as food packaging, i.e. as bottles or jars.

ZZS WIND SIFTER OPTIMIZES GLASS RECYCLING

Used glass processing with a high recycling rate

Used glass processing in Germany is the model pupil. If collected glass packaging such as bottles or jars are recycled, 60 % of white glass and 90 % of green glass cullet can be recycled into the new product. The remainder is sand, soda, lime, dolomite and feldspar. According to the Bundesverband Glasindustrie e. V., there are around 300,000 glass containers in Germany and the recycling rate was 83% in 2018. This means that 83% of container glass packaging was made from recycled glass. Windsifter technology from TRENNSO-TECHNIK® is used successfully, for example, to really get the most out of the glass thrown into the glass containers. The ZZS air separator plays an important role in glass recycling processing technology. It ensures efficient organic removal and thus helps to optimise the subsequent process steps and qualities.

Windsifter ZZS: sorting foreign matter from glass is his passion

Windsifter ZZS optimises glass recycling

A pile of broken glass also has its good side! When it comes to recycling, glass is a grateful raw material. Not only is glass one of the longest recycled materials in the circular economy, but the efficiency of glass recycling also makes other industries look on with envy. Glass can be 100% recycled, can be melted down as often as required and saves a lot of energy compared to initial production. According to DUH, energy consumption in glass production has fallen by around 77% over the past 50 years. This is thanks to modern technologies and successful glass recycling. The focus here is on its use as food packaging, i.e. as bottles or jars.

Used glass processing with a high recycling rate

Used glass processing in Germany is the model pupil. If collected glass packaging such as bottles or jars are recycled, 60% of white glass and 90% of green glass cullet can be recycled into the new product. The remainder is sand, soda, lime, dolomite and feldspar. According to the Bundesverband Glasindustrie e. V., there are around 300,000 glass containers in Germany and the recycling rate was 83% in 2018. This means that 83% of container glass packaging was made from recycled glass. Windsifter technology from TRENNSO-TECHNIK® for example, is used successfully to really get the most out of the glass thrown into the glass containers. The ZZS air separator plays an important role in glass recycling processing technology. It ensures efficient organic removal and thus helps to optimise the subsequent process steps and qualities.

Windsifter ZZS: sorting foreign matter from glass is his passion

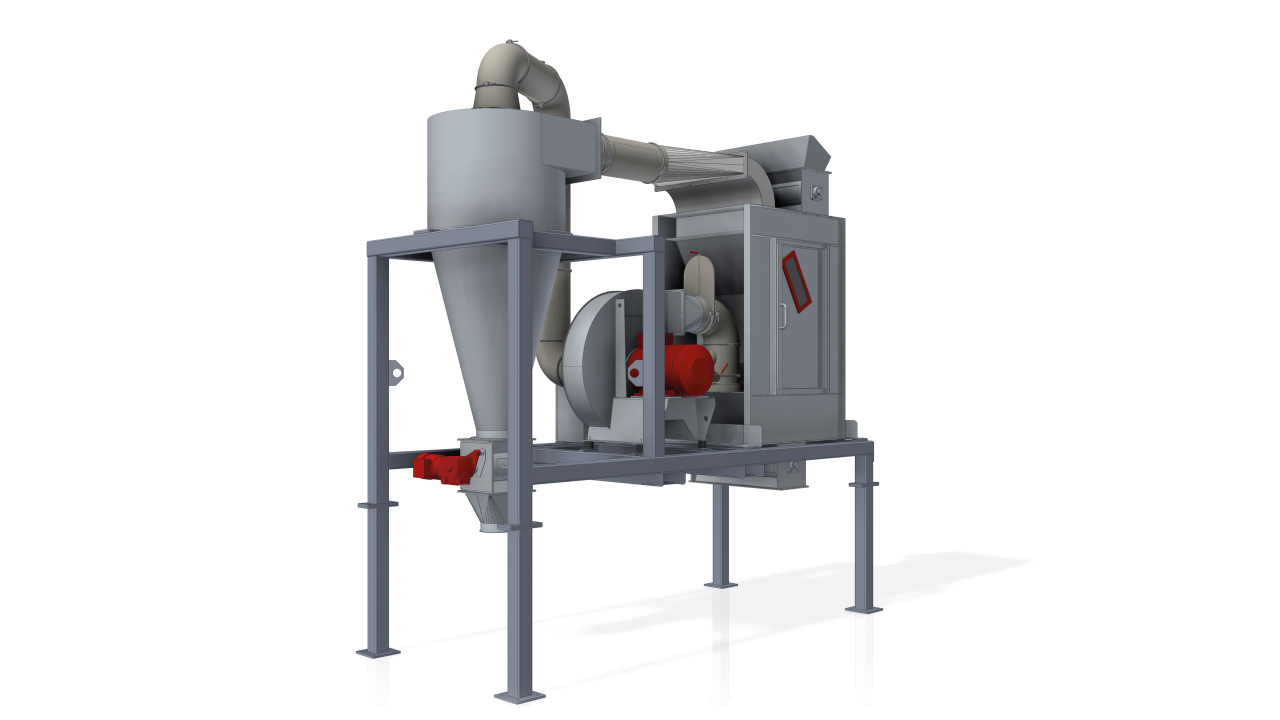

Glass or not glass, that is the question! In processing technology, a ZZS air separator is used as an organic separator to optimise the efficiency of glass recycling. Organic components such as film, paper, dust, lightweight plastics or corks are separated out by the air separator. The dry separation process used by TRENNSO-TECHNIK® uses pure air as the working medium. Operated in recirculating air mode, an air separator unit is therefore an environmentally friendly system from a sustainability perspective that consistently reflects the environmental concept of recycling.

The ZZS air separator in action separating glass and organics can be seen here in the Video or schematically in the animation.

In the airflow through the zig-zag sifter

The separated material enters the zig-zag separator via a rotary valve. Here it is distributed across the entire sifting channel cross-section and enters the air flow. The separating air generated by the blower flows through the separator from bottom to top, blowing through and separating the bulk material. At each bend in the separator channel, the product has to pass through the air flow and then collides with the opposite separator wall. The material with a higher density sinks downwards in the sifter channel as a result of gravity. Light material is sucked out of the separator channel in the upward air flow. The air speed of the blower is controlled by a frequency converter. Discharged air with the separated organics is cleaned via a cyclone separator.

By playing the video, you consent to the Google Privacy Policy Show more

We would like to point out that after being activated (consent according to Art. 49 Para. 1 P. 1 lit. a GDPR), data will be transferred to YouTube/Google ( Google Privacy Policy ) in the USA. The USA is considered by the European Court of Justice to be a country with a level of data protection that is inadequate by EU standards. If you do not use YouTube, the transfer described above will not take place.

Close overlayGlass recycling: a tough job?

Each air separator unit from TRENNSO-TECHNIK® is manufactured individually according to customer-specific requirements. Depending on the abrasiveness of the material to be separated, HARDOX, PU, stainless steel or ceramic, for example, can be used. For glass recycling, the air separator ZZS is equipped with hardfaced, replaceable impact plates. Ceramic is used in the pipework and cyclones. Systems from TRENNSO-TECHNIK® are also available in stainless steel and with customised surface finishes. Thanks to our decades of experience with a wide variety of feed products, we know the optimum system configuration for customised solutions in density sorting. Tests in our in-house technical centre support our process solution expertise.

Versatile zig-zag separator: from waste glass to non-precious metal processing to sand

Windsifter technology from TRENNSO-TECHNIK® can be used in a variety of ways to ensure the purity of fractions for further sorting steps. Zig-zag separators are successfully used as a density separation process not only for sorting used glass, but also for other bulk materials, other recycling areas or in the food sector.

Some examples for the use of ZZS air separators are:

Processing of used glass and glass production waste

Separation of non-ferrous metals from cable fractions

Dedusting of slag

Processing of shredder fractions

Sorting of household waste

Processing of compost

Separation of artificial turf

Pollutant removal from waste wood

Cleaning of sand

Cleaning of tea, herbs, spices, grain, nuts

Dry separation process: Moisture? No thanks!

Air separation technology is a dry separation process. The prerequisite for this is dry bulk material and a dry air flow. If moisture accumulates in the air flow, the sorting results will not be satisfactory. For this reason, highly efficient separation results are achieved through automatic exhaust air control.

TRENNSO-TECHNIK® optimises used glass recycling

The use of processing technology such as the ZZS windsifter from TRENNSO-TECHNIK® also helps to improve the efficiency of glass recycling. The objective of recovering the highest possible proportion of recyclable used glass is achieved when glass fractions are successfully pre-sorted. This is achieved with a high degree of purity by integrating machines and modules such as the ZZS wind sifter.

Questions about sorting technology? Call TRENNSO-TECHNIK®!

If you have any questions about sorting technology such as our screening technology or density sorting technology, we will be happy to inform you about our machine portfolio. Special feasibility enquiries can be carried out in real life through tests in the technical centre of TRENNSO-TECHNIK® in Weißenhorn. Our trained team in the technical centre will be happy to assist you by prior appointment.

We look forward to receiving your enquiry: Tel. +49 730996200 or an email info@tst.de