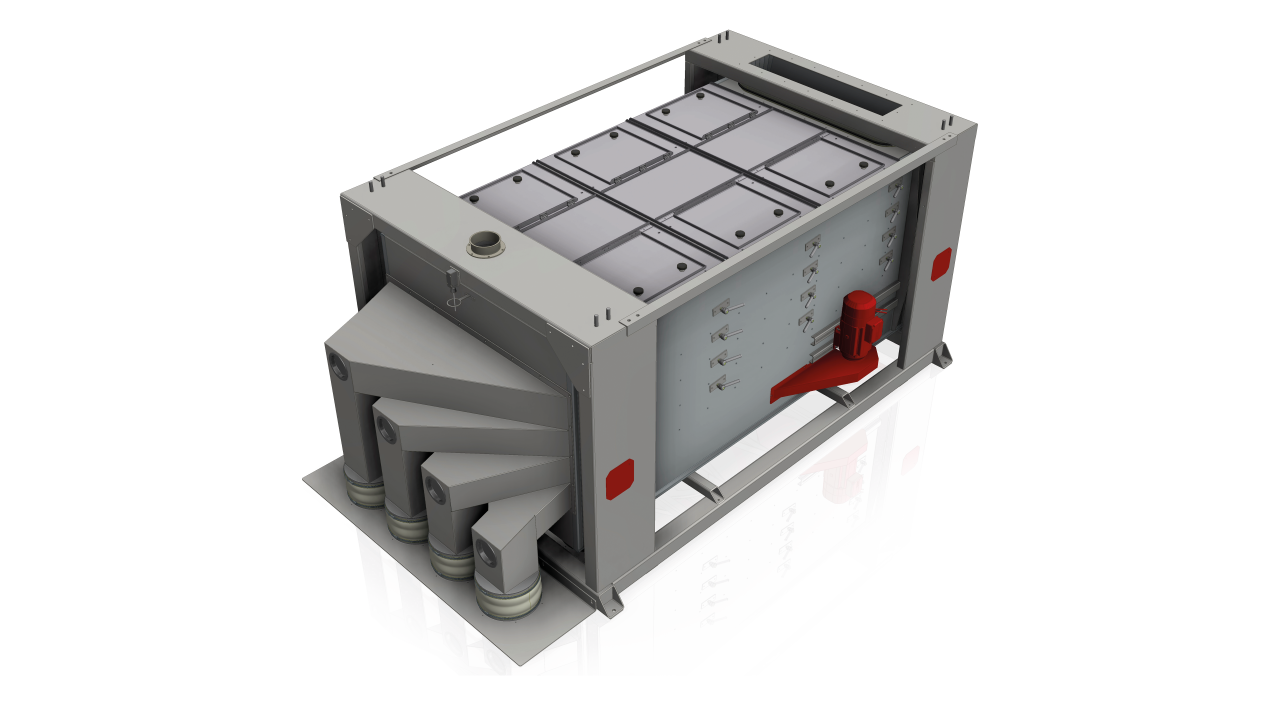

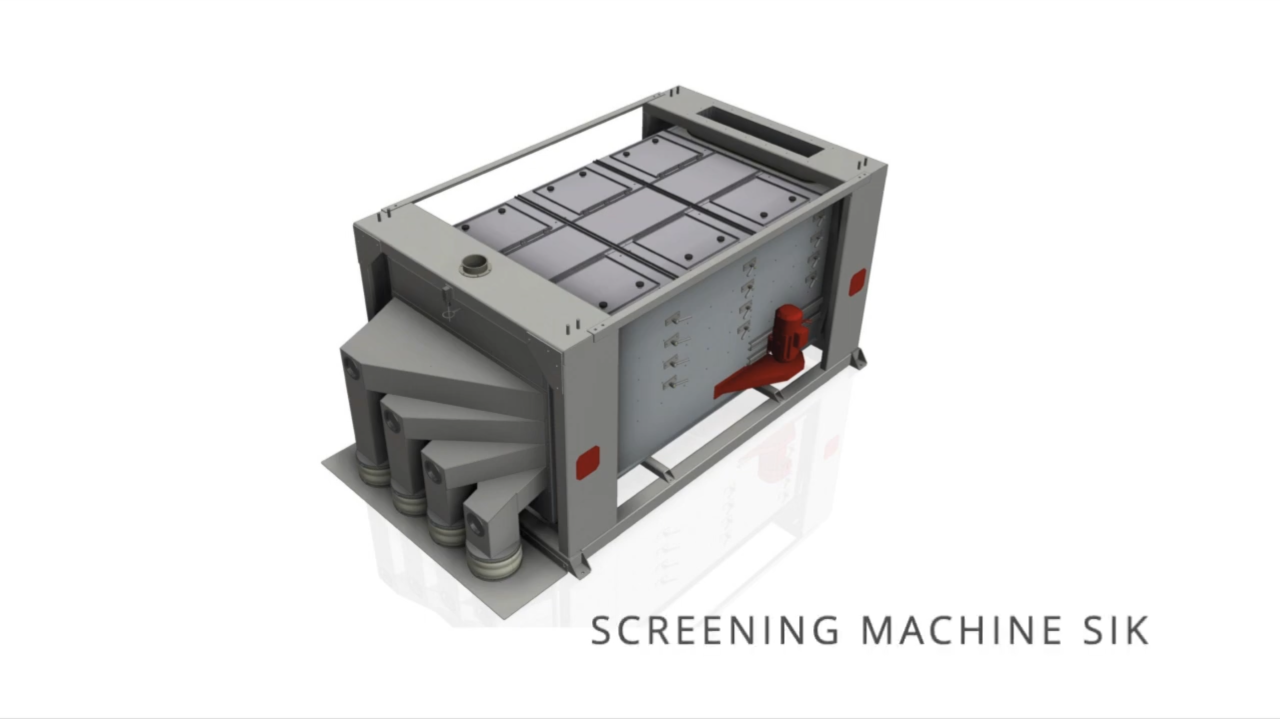

The XXL version is one of the largest single machines in the product portfolio of TRENNSO-TECHNIK®: The SIK.

Screening machines from TRENNSO-TECHNIK® are efficient in the classification of granular and floury bulk materials of different grain sizes. A certain moisture content should not be exceeded. The dimensions of the SIK can exceed those of some small cars.

SIK – LET'S SIFT BULK MATERIAL

4200 mm - The long journey on the sieve

The SIK screening machine is customised in design and dimensions according to customer requirements. From the smallest SIK 500/1200-1 to the currently largest SIK 2000/4200-5, we cover all customised solutions. The free-flowing bulk material can sometimes travel over four metres along the screening track. The end result is efficient separation into a maximum of 6 screen fractions;

From cable recycling to slag processing

A SIK screens dry bulk materials. If they are free-flowing and up to 40 mm in size in the starting material, our screening machine does its job reliably. The SIK screening machine is frequently used for separating

Glass recycling

Cable recycling

Slag recycling

NE metals

Wood

and many other applications.

Screening machines from TRENNSO-TECHNIK® meet the ever-increasing quality requirements of industrial recycling in terms of efficiency. This makes it a valuable component in the recycling and recovery process of high-quality secondary raw materials such as copper and other non-ferrous metals.

SIK - completely dry dust-tight sieving

The screenings are fed into the uppermost screen box via a distribution device. The screen boxes are freely suspended and dust-tight. An electric motor causes the screen boxes to vibrate horizontally. The separated fractions of the screen layers run into the screen outlets attached at the end or bottom. There, the screened bulk material can be fed into further process steps, for example, or transported for packaging or loading. The schematic function of a SIK screening machine can be seen here in the video:

By playing the video, you consent to the Google Privacy Policy Show more

We would like to point out that after being activated (consent according to Art. 49 Para. 1 P. 1 lit. a GDPR), data will be transferred to YouTube/Google ( Google Privacy Policy ) in the USA. The USA is considered by the European Court of Justice to be a country with a level of data protection that is inadequate by EU standards. If you do not use YouTube, the transfer described above will not take place.

Close overlaySieve insert - safe and convenient

The individual sieve layers are removed separately in segments from the rear of the machine. All sieve layers have a ball bottom cleaning system to clean the sieves continuously during the process and thus guarantee the sieve quality. The design is customised: from coarse perforated plate to fine mesh, 0.1 mm to 30 mm, in standard round or square mesh as well as in screen specifications specially developed by TRENNSO-TECHNIK® everything is possible. Based on years of experience plus possible trials in the TRENNSO technical centre, we configure the most efficient screen inserts for every suitable material;

Options and accessories for screening machines

Our SIK screening machine can also be connected to an aspiration system. The pneumatic screen clamping system is a new optional safety feature and saves even more time when changing screens. If desired, this can also be integrated into the overall control of the system. This ensures that the machine only works when all screens are fixed. HARDOX, PU, stainless steel and ceramic are available as wear linings. A complete version in stainless steel and customised surface finishes for the SIK screening machine are also available.

Siebtechnik made by TRENNSO-TECHNIK®

In addition to the SIK, there are other efficient screening solutions in screening technology from TRENNSO-TECHNIK®. Whether the TSM, RSS or SIS models - what all our screening machines have in common is that we find the optimum solution for our customers' tasks. On request as a single machine or integrated into a turnkey plant, which TRENNSO-TECHNIK® also designs, produces and supplies for customers operating worldwide. The optimum plant configuration is supported by 3D CAD in engineering and trained, experienced employees. Our system designs are regularly confirmed by the knowledge we gain from tests in our in-house technical centre;

Questions about sorting technology? Call TRENNSO-TECHNIK®!

If you have any questions about sorting technology such as our screening technology or density sorting technology, we will be happy to inform you about our machine portfolio. Special feasibility enquiries can be carried out in real life through tests in the technical centre of TRENNSO-TECHNIK® in Weißenhorn. Our trained team in the technical centre will be happy to assist you by prior appointment.

We look forward to receiving your enquiry: Tel. +49 730996200 or an email info@tst.de