According to the Federal Statistical Office, more than 50 million tonnes of industrial and commercial waste were generated in Germany in 2019. This represents an enormous burden on the environment. A large proportion of this waste is sent to landfill. Incineration in waste incineration plants is also a popular disposal method. However, there are also ways of utilising the waste. For example, it is possible to extract energy from it and use it for cement production. Commercial and industrial waste is ideal for this.

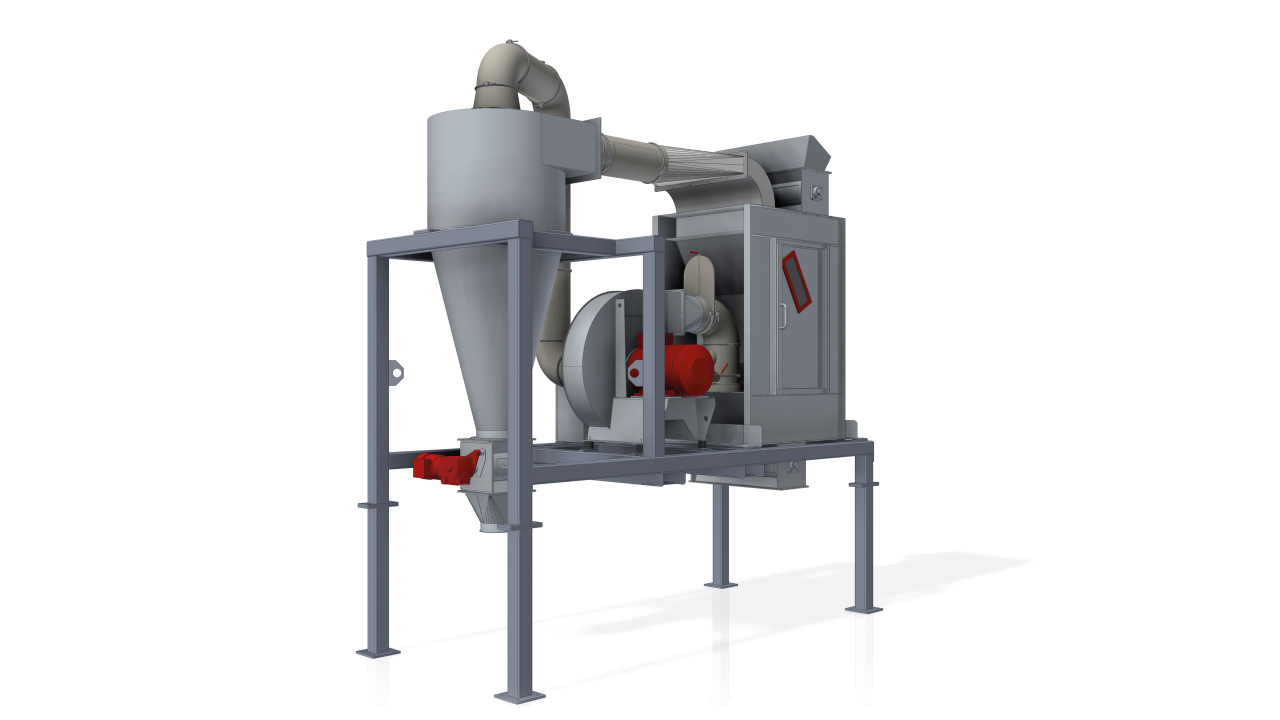

ZZS WIND SIFTER - SEPARATION OF SUBSTITUTE FUEL

Separation of substitute fuel for environmentally friendly energy generation

A lot of waste contains a lot of energy

For most people, rubbish is a worthless object that only needs to be disposed of as quickly as possible. However, waste is often not quite as worthless as it seems at first glance. Many of the materials that are no longer needed contain a lot of energy. For example, waste contains plastics, paper, wood and other materials that can be used as fuel. This can not only pay off financially. It also benefits the environment. Firstly, in this case it is not necessary to store the waste in landfill sites. Therefore, the landscape is not polluted. Secondly, this energy can be used to replace fossil fuels. The corresponding materials are referred to as substitute fuels.

Separation of waste materials is very important

Using waste as fuel is not a fundamentally new idea. This has been implemented in waste incineration plants for decades. However, the waste is usually incinerated unsorted. However, as it also contains many non-combustible substances, this means that the incineration process cannot run optimally. This severely restricts the possible uses. It is therefore very important to separate out the combustible materials beforehand. This enables a better combustion process and therefore many additional application possibilities.

Sorting is usually based on the density of the materials. Light materials such as paper or plastic are normally combustible, while heavy materials such as metal or glass are not suitable for incineration. However, most waste only contains around 20 per cent light materials. The vast majority, 80 per cent, is heavy waste. This also shows how important sorting is, as the majority of waste is not suitable for energy recovery. However, heavy waste can often be recycled in other ways. For example, after this pre-sorting it is much easier to separate metals or glass and then recycle these materials.

By playing the video, you consent to the Google Privacy Policy Show more

We would like to point out that after being activated (consent according to Art. 49 Para. 1 P. 1 lit. a GDPR), data will be transferred to YouTube/Google ( Google Privacy Policy ) in the USA. The USA is considered by the European Court of Justice to be a country with a level of data protection that is inadequate by EU standards. If you do not use YouTube, the transfer described above will not take place.

Close overlaySeparating waste with the WINDSICHTER ZZS

To sort the waste according to its density, you can use the WINDSICHTER ZZS from TRENNSO-TECHNIK® . This device has a so-called zigzag sifter. This is a vertical channel that has several kinks. The waste can be fed into the sifter via a rotary valve. A strong air flow is then applied here and channelled into the duct from below. This principle alone separates the waste materials according to their density. The air flow pulls the light parts upwards, while the heavy waste materials remain on the floor.

The special zig-zag shape of the separator leads to even more reliable separation. This is because heavier and lighter materials often stick together. However, when they hit a kink, they are diverted to the side and collide with great force against the side wall. This causes them to separate from each other. By repeating this process for several kinks, a very reliable separation is achieved. It is possible to regulate the speed of the air flow. This makes it possible to adapt the separation of the materials precisely to the requirements.

Utilise the sorted waste materials

Once the waste materials have been separated, they can be used as a source of energy. They are used particularly frequently in cement works. Cement production requires a lot of energy and leads to considerable CO2 emissions. However, the use of substitute fuels from waste makes it possible to significantly reduce the need for fossil fuels. As a rule, so-called co-incineration is used here, in which the waste materials are incinerated together with fossil fuels.

Questions about sorting technology? Call TRENNSO-TECHNIK®!

If you have any questions about sorting technology such as our screening technology or density sorting technology, we will be happy to inform you about our machine portfolio. Special feasibility enquiries can be carried out in real life through tests in the technical centre of TRENNSO-TECHNIK® in Weißenhorn. Our trained team in the technical centre will be happy to assist you by prior appointment.

We look forward to receiving your enquiry: Tel +49 730996200 or an email info@tst.de